THE INSTITUTE Like so many healthcare facilities around the world, hospitals in London are in short supply of personal protective equipment such as face shield visors. To help meet the demand, faculty members and students from the engineering and dentistry schools at the Queen Mary University of London teamed up to produce reusable visors using 3D printers.

The team includes IEEE members Ildar Farkhatdinov, Joshua Brown, and Kaspar Althoefer. Farkhatdinov and Althoefer are robotics professors. Althoefer is also a member of the IEEE Robotics and Automation Society. Brown is a student from the school’s Robotics, Electronics and Manufacturing lab.

Shakeel Shahdad, a professor of restorative dentistry, leads the project. Also lending a helping hand are dental students Ahmend Din and Ho Huen Kok.

This project started in early April, and since then the team has produced and delivered more than 1,500 visors. The team aims to eventually manufacture 50,000 visors per day.

The Institute asked Farkhatdinov about the project.

This interview has been edited and condensed for clarity.

What problem are you trying to solve?

Hospitals in the United Kingdom are experiencing an increase in demand for PPE, and existing supply chains are struggling to keep up. We designed and organized the manufacturing of reusable visors, which we supply to several hospitals in London.

What technologies are you using?

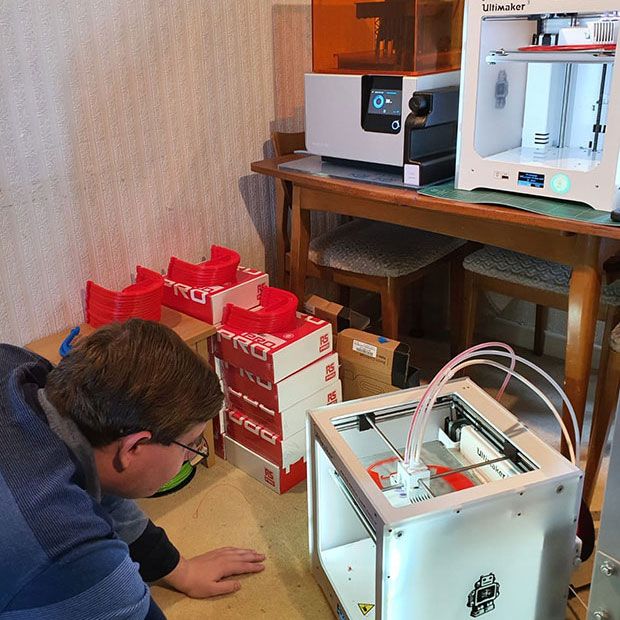

Our primary technology is 3D printers and stereolithography and fused deposition modeling. Stereolithography uses a liquid resin to produce an object with a 3D printer while fused deposition modeling uses thermoplastic filaments.

Explain how your project works.

We use inexpensive traditional 3D printers, which are easy to set up and operate at home. However, the speed of production is slow. We currently produce 100 visors a day but we have developed a prototype of the visor using injection molding, which creates parts by injecting molten material into a mold. This will increase the production to up to 50,000 units per day.

What challenges have you faced and how did you overcome them?

It was challenging to organize regular delivery of the manufactured visors because of the travel restrictions imposed in London and the rest of the U.K.

It was also difficult to find a sufficient supply of materials, such as printing filament and acetone sheets for the visors. Because similar such COVID-19 manufacturing projects are also purchasing supplies, there aren’t enough for all of us.

To overcome this, we are working hard with our industrial partners to establish new supply chains. We recently partnered with Halma, Batch.works, and Keratify to mass-produce the PPE. Halma is a healthcare technology manufacturer while Batch.works and Keratify are 3D printing companies.

We are also working closely with several manufacturing companies and startups that will help us establish mass-production. We plan to apply for certification through the British Standards Institution, which we will submit within the next two weeks.

The project also has funding from the university as well as donations from the nonprofit Barts Charity, which supports healthcare-centered projects.

What is the potential impact of the technology?

We have already received positive feedback from those who work in the emergency department in our university’s hospital, Barts Health NHS Trust.

How many people are involved?

In addition to the core team, more than 15 academics, researchers, staff, students, and alumni from the university are involved.

How can other IEEE members get involved?

If you are based in the London area and are interested in contributing to our project, you can email me.

Attention IEEE members: are you part of a team responding to the COVID-19 crisis? We want to hear from you! Wherever you are and whatever you are doing, if you are helping deal with the outbreak in some way, let us know. Send us accounts of anywhere from 200 to 800 words, or simply give us a rough idea of what you are doing and your contact information. Write to: k.pretz@ieee.org